The reverse flame hot water boiler is a highly efficient and versatile system designed to deliver high performance in terms of energy efficiency and emission reduction. This type of boiler is suitable for industrial and commercial applications, with a power range from 65 kW to 7000 kW.

-

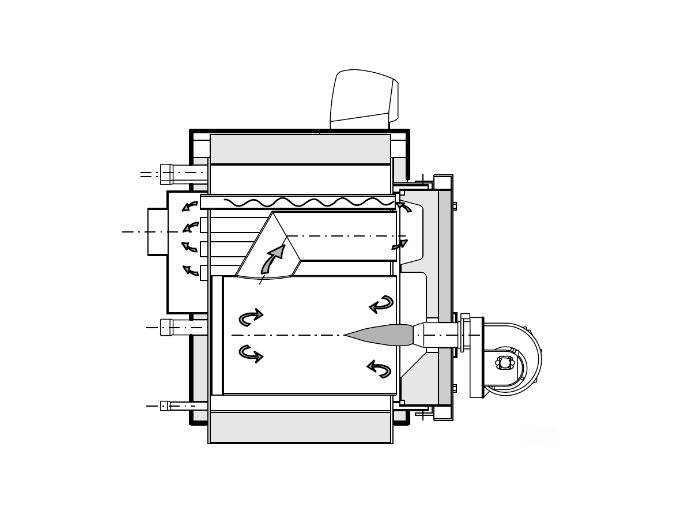

Reverse Flame Technology:

The boiler uses the reverse flame principle, where the flame propagates in the opposite direction to the normal flow of combustion gases, optimizing heat transfer and improving the thermal process efficiency.

-

Wet Bottom Configuration:

The wet bottom configuration allows better heat transfer from the bottom surface to the water mass, increasing efficiency and reducing the risk of overheating and damage to the boiler.

-

Power Range from 65 kW to 7000 kW:

The boiler is available in various sizes, with a power output ranging from 65 kW to 7000 kW, making it suitable for a wide range of applications, from small businesses to large industries.

-

High Efficiency (>94%):

The boiler ensures an efficiency greater than 94%, meaning that a large portion of the energy produced from combustion is effectively used to heat the water, minimizing waste and improving energy efficiency.

-

Low NOx Emissions:

Thanks to advanced technology, the boiler is designed to minimize nitrogen oxide (NOx) emissions, helping to meet the strictest environmental regulations and reducing its environmental impact.

-

Steel Turbulators for Optimized Heat Exchange:

The boiler includes steel turbulators that help optimize heat exchange, enhancing the overall efficiency of the system by improving the flow of combustion gases and heat transfer.

-

Complete with Control Panel:

The boiler comes fully equipped with a control panel to monitor and manage the operation, ensuring precise control over temperature, pressure, and system performance for maximum reliability and efficiency.