- Brescia, Via fratelli Ugoni, 32 - 25126 Italy

- +39 030 25 59 291

- info@avogadroenergy.com

- +39 351 89 84 188

Energy Independence in Remote Locations: 350 kW Dual-Fuel Solution

How we solved the logistical challenges of an exclusive resort on a Romanian island with a system capable of transforming waste into heat.

The Challenge

Operating in an isolated geographical context requires a resilient energy strategy. The client required a thermal plant that was not tied solely to the supply of liquid fuels. Instead, the system needed to leverage locally available solid resources to ensure service continuity and reduce fuel transportation costs.

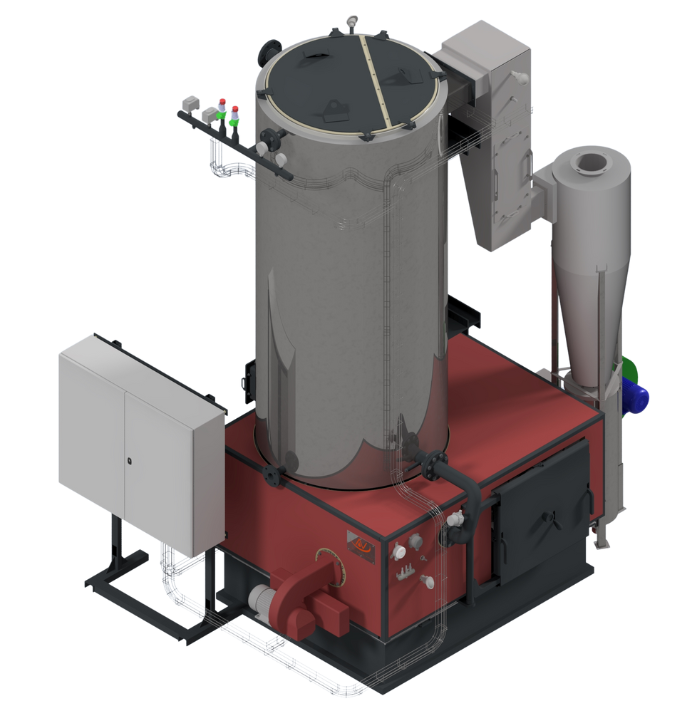

The Tailored Solution: ECO-BURN 350 (Compact)

We developed a custom plant designed specifically for integration into pre-existing boiler rooms, featuring cutting-edge technical specifications:

-

Dual-Fuel System: The unit is capable of operating with fuel oil or solid materials, offering total operational flexibility.

-

Power and Control: A 350 kW capacity managed via PLC and inverter, which optimizes the combustion air fan for consistently efficient performance.

-

Energy Recovery: The system upcycles what would normally be considered waste, producing hot water at 105°C.

-

Air Quality: The integration of a cyclone dust collector ensures a dust separation efficiency of over 90%, minimizing environmental impact in compliance with regulations.

Customization and Scalability

Based on the specific needs of this project, the system features manual loading for solid fuel. However, Avogadro Energy’s expertise allows for the configuration of similar solutions with automatic feeding systems for biomass plants requiring continuous, unmanned operation.

Send us an email for more information