- Brescia, Via fratelli Ugoni, 32 - 25126 Italy

- +39 030 25 59 291

- info@avogadroenergy.com

- +39 351 89 84 188

SVT - Rapid Steam Generator with Boiler Operator Exemption

SVT: rapid steam generator, exempt from licensed operator and commissioning (D.Lgs 93/2000). Safe, compact and ready for industrial use.

SVT - Rapid Steam Generator with Operator Exemption

The SVT model boilers with standard pressure are classified as boilers that, according to Legislative Decree no. 93/2000, do not require continuous supervision by a qualified operator (licensed fireman) nor do they require a specific commissioning procedure.

D.Lgs no. 93/2000 – Art. 2, Exemptions, point F

Art. 2 – Exemptions

- Pressure equipment for quick coffee preparation

- Domestic pressure cookers

- Generators, vessels and pipelines with a maximum allowable pressure not exceeding 0.5 bar

- Fixed fire extinguishers with max allowable pressure ≤10 bar or inner diameter <400 mm; portable extinguishers with gas cartridge ≤18 bar

- Steam or hot water generators with total volume ≤25 liters and max pressure ≤32 bar

- Steam or hot water generators where the product of max pressure (bar) × volume (liters) ≤300, and max allowable pressure ≤10 bar

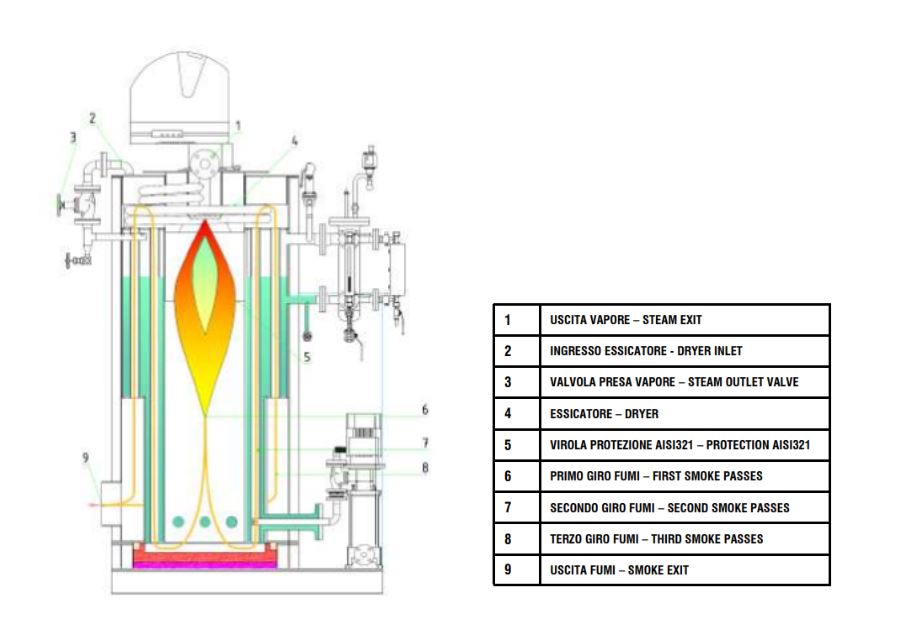

Pressure body: Made of certified carbon steel sheet, vertical cylindrical structure, welded to tube plates and equipped with connections for valves and instrumentation.

Furnace: Built in certified carbon steel, vertical cylindrical shape, designed for optimal mixing of fuel and combustion air, ensuring efficient combustion.

Operator exemption: According to Legislative Decree no. 93/2000, no continuous supervision by a licensed fireman is required, nor any specific commissioning procedure.

Regulation equipment: Pressure probe, electronic pressure controller, ON/OFF level control system with probes for pump management.

Control equipment: Standard pressure gauge with shut-off valve and test flange; reflection level indicators; electronic pressure indicator integrated in the panel.

Safety equipment: Certified high-pressure safety switch; approved safety valve; double low-level safety controller with manual reset.

Valves: Steam take-off valve; water inlet check/interception valve; pneumatic and manual blowdown valves; alkalinity discharge valve.

Feed unit: ON/OFF centrifugal pump compliant with current regulations, mounted on a base, resistant up to 120°C, with high-pressure flexible hose.

Electric panel: Painted steel box IP54 with main safety switch, pump and burner switches, motor contactor, 24V auxiliary transformer, fuses, signal lamps, reset and start buttons.

Stainless steel version: Available on request in AISI 304 or AISI 316, compliant with HTM 2031 Standard, for the production of clean steam for healthcare, pharmaceutical, and food industries.

HTM 2031 clean steam: Ensures condensate quality meets BP Water for Injection standards, ideal for hospital sterilization and pharmaceutical/food processes.

| Model | Steam (kg/h) | Power (kW) | Length (mm) | Width (mm) | Height (mm) |

|---|---|---|---|---|---|

| SVT 45 | 45 | 30 | 800 | 1400 | 1500 |

| SVT 90 | 90 | 60 | 800 | 1400 | 1500 |

| SVT 130 | 130 | 87 | 800 | 1400 | 1500 |

| SVT 160 | 160 | 107 | 800 | 1400 | 1750 |

| SVT 230 | 230 | 154 | 800 | 1400 | 1750 |

| SVT 280 | 280 | 187 | 800 | 1400 | 1750 |

| SVT 340 | 340 | 227 | 800 | 1400 | 1750 |

| SVT 410 | 410 | 274 | 1000 | 1500 | 2100 |

| SVT 500 | 500 | 335 | 1000 | 1500 | 2075 |

| SVT 750 | 750 | 502 | 1000 | 1500 | 2310 |

| SVT 1000 | 1000 | 670 | 1000 | 1500 | 2415 |

| SVT 1250 | 1250 | 837 | 1200 | 1700 | 2670 |