- Brescia, Via fratelli Ugoni, 32 - 25126 Italy

- +39 030 25 59 291

- info@avogadroenergy.com

- +39 351 89 84 188

SW – Steam Generator with Coil

SW: coil steam generator, 100–4,000 kg/h (up to 10,000 on request), high efficiency, low NOx emissions, exempt from licensed operator.

SW - Steam Generator with Coil

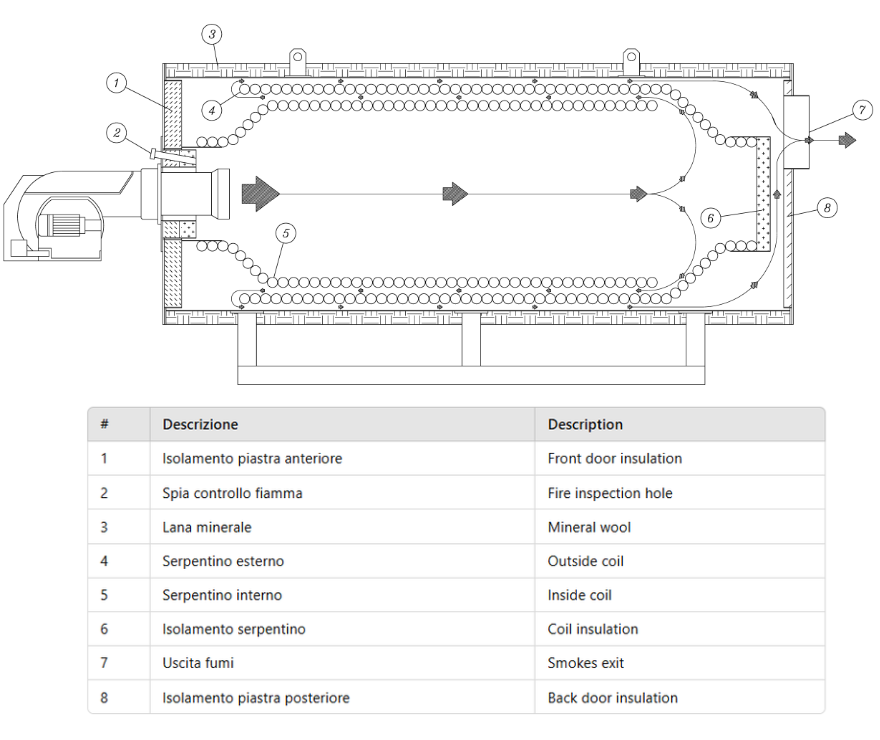

The SW coil steam generator is designed to deliver high efficiency and energy savings, ensuring instantaneous steam production and a management system in compliance with the latest safety regulations. Falling into the category of generators exempt from licensed operation (according to Annex III of the Italian Ministerial Decree of August 7, 2020), it does not require the presence of a qualified operator, making it particularly versatile and easy to manage in industrial environments.SW – Steam Generator with Coil

This SW series generator is ideal for applications requiring safe and instantaneous steam with minimal maintenance needs and without the constraints of licensed operation.

SW Forced Circulation Steam Generators

(Available in both Horizontal and Vertical configurations)

| Model | Steam Production (kg/h) | Power (kW) | Length L (mm) | Width W (mm) | Height H (mm) |

|---|---|---|---|---|---|

| SW 120 | 120 | 84 | 1,750 | 1,500 | 1,650 |

| SW 200 | 200 | 140 | 1,750 | 1,500 | 1,650 |

| SW 300 | 300 | 209 | 1,750 | 1,500 | 1,650 |

| SW 400 | 400 | 279 | 1,750 | 1,500 | 1,650 |

| SW 500 | 500 | 349 | 1,750 | 1,500 | 1,650 |

| SW 600 | 600 | 419 | 2,300 | 1,500 | 1,700 |

| SW 800 | 800 | 558 | 2,300 | 1,500 | 1,700 |

| SW 1000 | 1,000 | 698 | 2,300 | 1,500 | 1,750 |

| SW 1200 | 1,200 | 837 | 2,300 | 1,500 | 1,750 |

| SW 1500 | 1,500 | 1,047 | 3,350 | 1,700 | 2,000 |

| SW 2000 | 2,000 | 1,396 | 3,350 | 1,700 | 2,000 |

| SW 2500 | 2,500 | 1,745 | 3,850 | 1,800 | 2,200 |

| SW 3000 | 3,000 | 2,093 | 3,850 | 1,800 | 2,200 |

| SW 3500 | 3,500 | 2,442 | 4,350 | 1,900 | 2,300 |

| SW 4000 | 4,000 | 2,791 | 4,350 | 1,900 | 2,300 |

| SW 4500 | 4,500 | 3,140 | 4,850 | 2,000 | 2,400 |

| SW 5000 | 5,000 | 3,489 | 4,850 | 2,000 | 2,400 |

| SW 5500 | 5,500 | 3,837 | 5,350 | 2,100 | 2,500 |

| SW 6000 | 6,000 | 4,186 | 5,350 | 2,100 | 2,500 |

| SW 6500 | 6,500 | 4,535 | 5,850 | 2,200 | 2,600 |

| SW 7000 | 7,000 | 4,884 | 5,850 | 2,200 | 2,600 |

| SW 7500 | 7,500 | 5,233 | 6,350 | 2,300 | 2,700 |

| SW 8000 | 8,000 | 5,581 | 6,350 | 2,300 | 2,700 |

General Specifications:

- Design Pressure: 11.76 bar (available up to 100 bar).

- Efficiency without economizer: 93% (±1%).

- Efficiency with economizer: 96% (±1%).